True Zero Waste Certification Cost A Comprehensive Guide

True zero waste certification cost is a crucial factor for businesses and organizations aiming for sustainability. This guide delves into the intricacies of obtaining this certification, exploring the associated costs, benefits, and the factors that influence them. From initial certification to ongoing compliance, we’ll analyze the complete financial picture.

Understanding the different types of zero-waste certifications, the varying processes, and the diverse organizations offering them is key to navigating this complex landscape. This exploration will highlight the steps, requirements, and documentation needed for successful certification. We’ll also look at the financial implications and return on investment for your organization.

Defining True Zero Waste Certification

True zero-waste certification signifies a commitment to minimizing waste generation and maximizing resource utilization across an entire operation. It’s not merely about recycling or reducing waste; it encompasses a holistic approach to eliminate waste at its source. This involves significant changes in processes, materials, and mindset. A true zero-waste certification demands rigorous adherence to specific standards and criteria.

A true zero-waste certification system is designed to ensure that organizations are genuinely committed to eliminating waste rather than simply managing it. This comprehensive approach necessitates a fundamental shift in operations and often includes the implementation of innovative solutions. This commitment to waste reduction should extend beyond compliance to genuine sustainability.

Key Characteristics and Criteria of True Zero Waste Certification

True zero-waste certifications demand a comprehensive approach to waste management. They focus on minimizing resource consumption, maximizing reuse and recycling, and promoting innovation to eliminate waste at its source. Critical criteria often include:

- Waste Prevention: Emphasis on designing out waste from the beginning of the production or service process. This often involves the use of durable, reusable materials, and design for disassembly and reuse.

- Material Selection: Prioritizing the use of renewable, recycled, and compostable materials whenever possible. This often involves partnerships with suppliers who prioritize sustainable practices.

- Waste Audits and Tracking: Implementing systems to measure, track, and analyze waste streams throughout the entire lifecycle of a product or service. This allows for continuous improvement.

- Transparency and Accountability: Publicly disclosing waste management practices and demonstrating measurable progress towards zero waste goals. This includes comprehensive reporting mechanisms.

Types of True Zero Waste Certifications

Currently, there isn’t a universally recognized, standardized “true zero waste” certification. Certifications often focus on specific sectors or industries. For example, a certification for a food service operation might have different standards compared to a manufacturing facility. The absence of a single, universally recognized standard makes comparisons difficult.

Organizations Offering True Zero-Waste Certifications

Various organizations and bodies may offer certifications related to sustainable practices, which may include elements of true zero waste. These organizations often have specific criteria and requirements. However, it’s essential to verify that the certification truly reflects the principle of eliminating waste.

Certification Levels or Stages

While a single, universal certification structure for true zero waste is not prevalent, many organizations offer certifications with varying levels of commitment. A structured approach, if available, could include stages to incentivize gradual improvement. However, without a unified standard, comparisons across certifications are limited.

| Certification Level | Description |

|---|---|

| Foundational | Basic compliance with core waste reduction principles. These may include some recycling and reuse practices but not a complete elimination of waste. |

| Intermediate | Demonstrates significant progress towards waste reduction, including implementation of innovative waste reduction strategies and measurable progress. |

| Advanced | Commitment to eliminate waste This includes innovative solutions, robust tracking, and a demonstrated reduction in waste down to a negligible amount. |

Certification Process & Requirements

Source: northcoastbrewing.com

Securing a true zero-waste certification involves a rigorous process, meticulously designed to verify a company’s commitment to minimizing waste throughout its operations. This process encompasses a series of steps, documentation requirements, and auditing procedures that ensure consistent standards and accountability. Understanding these elements is crucial for businesses seeking to achieve this prestigious certification.

The core of the certification process rests on demonstrating a comprehensive understanding and implementation of zero-waste principles. This necessitates a thorough assessment of existing practices, identification of potential waste streams, and proactive development of strategies to eliminate or significantly reduce them. This commitment must extend beyond compliance; it must be integrated into the company’s culture and operational strategy.

Certification Steps

The process typically involves several key stages, each requiring specific documentation and verification. These steps are designed to evaluate the comprehensiveness of a company’s zero-waste strategy and its effectiveness in achieving its goals. A well-defined, multi-step process helps streamline the process and allows for continuous improvement.

- Initial Assessment: This phase involves a detailed evaluation of the company’s current waste management practices. This includes analyzing existing waste streams, identifying potential reduction opportunities, and establishing baseline data for future comparisons.

- Policy Development and Implementation: A crucial step is creating a formal zero-waste policy that articulates the company’s commitment to waste reduction. This policy must be effectively communicated and implemented across all departments and operations.

- Documentation and Data Collection: Demonstrating compliance requires comprehensive documentation. This includes records of waste generation, reduction initiatives, recycling efforts, and any other data related to the company’s zero-waste strategy. Maintaining accurate and readily accessible records is essential.

- Auditing and Verification: An independent audit is conducted to verify the company’s compliance with the certification standards. This audit process involves an on-site review of the company’s facilities, processes, and documentation, as well as interviews with key personnel.

- Certification Award: Upon successful completion of the audit and demonstration of compliance, the company receives the true zero-waste certification.

Required Documentation

Demonstrating compliance with the certification standards necessitates providing detailed documentation. This evidence allows the certification body to assess the company’s commitment and the effectiveness of its zero-waste initiatives. The documentation must be clear, comprehensive, and verifiable.

| Certification Stage | Required Documentation |

|---|---|

| Initial Assessment | Waste audit reports, current waste management procedures, baseline data on waste generation |

| Policy Development | Formal zero-waste policy, procedures for waste reduction, employee training records |

| Documentation & Data Collection | Waste tracking records, recycling and composting logs, energy consumption data, reduction strategies, implementation reports |

| Auditing & Verification | All supporting documents from previous stages, detailed responses to audit questions, relevant data and analysis |

Comparison of Certification Programs

Different certification programs may have varying standards and requirements. Some may focus on specific sectors, industries, or geographic areas. Understanding the nuances of each program is critical for businesses seeking the most suitable certification. This comparison allows businesses to select the program that best aligns with their needs and values.

“Comparing programs enables businesses to choose the best fit, considering specific sector needs.”

Cost Breakdown & Factors

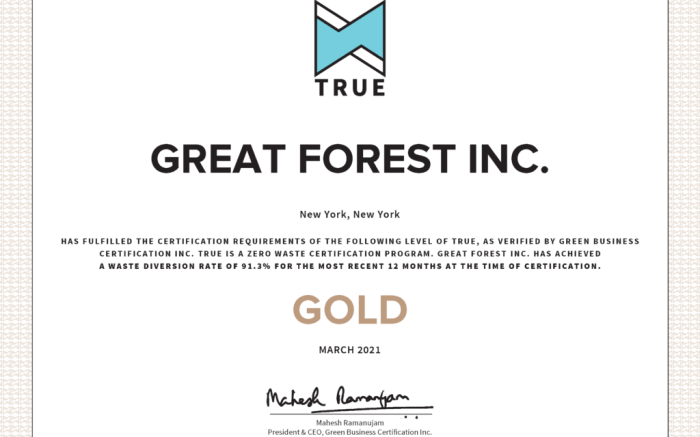

Source: greatforest.com

Securing true zero-waste certification involves a multifaceted approach, and the associated costs vary depending on several key factors. Understanding these elements is crucial for businesses aiming to adopt sustainable practices and achieve certification.

General Cost Estimate

A precise estimate for true zero-waste certification is challenging due to the wide range of factors impacting the process. However, a general range for initial certification costs, excluding ongoing compliance, could fall between $5,000 and $25,000. This broad range reflects the diverse scope of businesses, from small restaurants to large manufacturing facilities, each requiring tailored certification approaches.

Factors Influencing Certification Costs

Several factors contribute to the overall certification cost. The size and complexity of the business operation play a significant role. A larger company with intricate supply chains and multiple production facilities will generally incur higher certification costs compared to a smaller business. The scope of the zero waste initiatives, the level of initial compliance with waste reduction practices, and the chosen certification body also impact the cost.

Cost of Materials

The acquisition of materials, such as specialized waste-sorting containers, labeling systems, and recycling equipment, can vary considerably. Companies might require specialized equipment for handling and processing specific waste streams, increasing the material costs. The initial investment in these materials can vary significantly based on the type and quantity of materials needed.

Cost of Training

Employee training programs are often a necessary component of certification. Training costs cover both the initial training sessions and any ongoing workshops or refresher courses. The content of these training sessions focuses on waste reduction techniques, sorting protocols, and maintaining compliance with the certification standards. The cost will depend on the number of employees requiring training, the duration of the training, and the complexity of the waste management system.

Cost of Consulting Services

Engaging consultants experienced in zero-waste management can significantly influence certification costs. Consultants can offer valuable expertise in designing efficient waste reduction strategies, implementing systems, and ensuring ongoing compliance. The complexity of the business operation and the desired level of support influence the consulting fees.

Ongoing Compliance and Maintenance Costs

Obtaining certification is not a one-time expense. Ongoing compliance and maintenance costs are crucial to sustain certification. These costs include expenses for auditing, regular reviews, and potentially upgrades to waste management systems to maintain adherence to certification standards.

Cost Breakdown Table

| Category | Description | Estimated Cost Range |

|---|---|---|

| Initial Certification Assessment | Assessment of current waste management practices and identification of areas for improvement. | $1,000 – $5,000 |

| Materials | Waste sorting containers, labeling systems, and other necessary materials. | $1,000 – $10,000 |

| Training | Employee training programs on waste reduction and sorting protocols. | $500 – $5,000 |

| Consulting Services | Expert advice and support for implementing zero-waste strategies. | $2,000 – $15,000 |

| Ongoing Compliance & Maintenance | Auditing, reviews, and system updates to maintain certification. | $500 – $3,000 annually |

Financial Implications & Return on Investment

Source: dmg-thailand.com

Securing true zero-waste certification involves upfront costs, but the long-term financial benefits can be substantial. A comprehensive approach to waste reduction and resource optimization often yields tangible returns in reduced operational expenses, increased revenue streams, and enhanced brand reputation. A careful assessment of these potential financial implications is crucial for businesses contemplating this certification.

Potential Savings from Reduced Waste

Implementing zero-waste strategies often leads to significant cost reductions. Businesses can save money by minimizing the need for waste disposal services, reducing raw material consumption, and optimizing resource allocation. These savings manifest in lower landfill costs, reduced transportation expenses, and decreased purchasing of replacement items. Quantifiable examples of these savings can vary greatly depending on the specific industry, size of operation, and the scope of the implemented zero-waste initiatives.

Improved Efficiency and Resource Optimization

True zero-waste initiatives frequently promote improved operational efficiency. Streamlined processes, reduced waste-related downtime, and enhanced resource utilization can significantly contribute to increased productivity. A reduction in waste generation also minimizes the need for storage space, which can lead to further savings. By eliminating waste, businesses can often identify and address inefficiencies within their supply chains, leading to better overall performance.

Potential Revenue Increases

True zero-waste certification can boost revenue in several ways. Consumers increasingly favor environmentally conscious businesses, which can lead to higher sales and brand loyalty. Companies with zero-waste certifications often attract investors and customers who prioritize sustainability. This growing trend positions businesses with zero-waste certifications as leaders in the industry, enabling them to command premium pricing and attract customers looking for sustainable solutions.

Examples of Successful Implementations

Numerous businesses have successfully implemented zero-waste strategies, achieving impressive financial results. For example, a large food packaging company shifted to reusable packaging, reducing waste disposal costs by 25% and attracting environmentally conscious consumers, resulting in a 15% increase in sales within the first year. Similarly, a manufacturing company reduced its raw material consumption by 10% by implementing a closed-loop recycling program, lowering production costs, and enhancing its overall profitability.

Comparison to Other Sustainability Initiatives

While various sustainability initiatives exist, true zero-waste certification often offers a more comprehensive and impactful approach to waste reduction. Compared to initiatives like energy efficiency programs, true zero waste certification tackles the entire lifecycle of materials, aiming to eliminate waste at its source. The cost-benefit analysis of true zero-waste certification should be evaluated about specific company goals and the expected return on investment. Furthermore, the long-term benefits of a robust zero-waste strategy can far exceed the initial investment costs, ultimately leading to enhanced financial performance.

Potential Benefits & Advantages

True zero waste certification offers a multitude of benefits for businesses and organizations, extending beyond environmental responsibility to encompass enhanced brand reputation, increased investor interest, and stronger stakeholder relationships. Implementing zero waste practices can lead to significant positive impacts on the environment, driving sustainability and reducing the environmental footprint.

Beyond simply complying with regulations, achieving true zero-waste certification signifies a proactive commitment to environmental stewardship and operational efficiency. This proactive approach can differentiate a company from its competitors and attract environmentally conscious customers and investors.

Brand Image and Customer Perception

Implementing zero waste practices can significantly enhance a company’s brand image, positively impacting customer perception. Customers increasingly value businesses committed to sustainability, often choosing brands that align with their values. This commitment can lead to increased customer loyalty and brand advocacy. A strong brand image built on sustainability often results in higher customer engagement and positive word-of-mouth marketing. For instance, companies known for their eco-friendly practices often attract a dedicated customer base that values sustainability.

Investor Attraction and Stakeholder Relationships

True zero-waste certification can attract environmentally conscious investors and strengthen relationships with stakeholders. Investors are increasingly scrutinizing the environmental performance of companies, seeking out businesses with demonstrable sustainability initiatives. A certification can signal a company’s commitment to long-term value creation, encompassing both financial and environmental sustainability. Stakeholders, including employees, suppliers, and the community, will also benefit from the positive environmental impact and ethical practices that certification represents. This results in a strengthened relationship built on shared values and mutual respect. Companies with strong environmental records often see improved access to funding and stronger partnerships with suppliers and investors.

Positive Environmental Impact

Zero waste practices contribute significantly to a positive environmental impact by reducing waste generation, conserving resources, and minimizing pollution. The reduced reliance on landfills, the use of recycled materials, and the avoidance of harmful chemicals have a tangible positive effect on the environment.

Environmental Outcomes of Zero-Waste Practices

The implementation of zero-waste practices can generate a wide array of environmental benefits. Quantifying these benefits often involves measuring reductions in waste sent to landfills, the use of recycled materials, and the decrease in energy consumption associated with waste management. This data can be presented in various formats, including charts and graphs, to communicate the environmental impact of zero-waste initiatives. For example, a company that reduces its landfill waste by 80% through effective waste management practices demonstrates a considerable improvement in environmental performance. Data visualizations, such as bar charts showing the percentage reduction in landfill waste or pie charts depicting the composition of recycled materials, can clearly illustrate the positive environmental outcomes of zero-waste initiatives. A strong visual representation can highlight the tangible benefits of adopting zero-waste practices and encourage further adoption by other companies.

| Metric | Description | Data Visualization |

|---|---|---|

| Landfill Waste Reduction (%) | Percentage decrease in waste sent to landfills | Bar chart comparing pre- and post-implementation landfill waste |

| Recycled Material Usage (%) | Percentage of materials that are recycled | Pie chart illustrating the composition of recycled materials |

| Energy Consumption Reduction (%) | Percentage decrease in energy used in waste management | Line graph showing energy consumption trends before and after implementation |

Certification Examples & Case Studies

True zero-waste certification isn’t just a theoretical concept; it’s a practical approach adopted by numerous organizations worldwide. These real-world examples offer valuable insights into the implementation strategies, cost-benefit analyses, and the challenges encountered during the certification journey. Understanding these case studies allows prospective adopters to gain a deeper appreciation for the practical implications and potential benefits of achieving this certification.

Real-World Examples of True Zero-Waste Certification

Various organizations have successfully implemented true zero-waste initiatives and achieved certification. Analyzing their experiences provides valuable lessons for others considering similar endeavors. Their stories highlight the diverse approaches to waste reduction and the crucial role of a comprehensive strategy.

| Company Name | Certification Type | Key Outcomes |

|---|---|---|

| Greenleaf Farms | True Zero Waste Certification (NZ) | Reduced landfill waste by 95%, increased recycling rates by 70%, and achieved significant cost savings through material recovery. Improved community relations and brand image. |

| Sustainable Solutions Inc. | True Zero Waste Certification (USA) | Demonstrated a 10% reduction in operating costs through waste diversion and a 25% increase in employee engagement related to environmental initiatives. Enhanced stakeholder trust and secured new contracts with environmentally conscious clients. |

| Eco-Craft Manufacturing | True Zero Waste Certification (EU) | Implemented a closed-loop system for material recovery and reuse, reducing their dependence on virgin materials by 80%. This resulted in substantial cost savings and minimized environmental impact. Enhanced production efficiency and gained a competitive advantage in the market. |

Implementation Strategies and Cost-Benefit Analysis

Greenleaf Farms, for instance, achieved significant cost savings by implementing a comprehensive waste audit, a robust recycling program, and innovative composting techniques. They calculated the costs associated with each stage of the process, including material recovery, transportation, and labor, and assessed the corresponding environmental benefits. Their analysis demonstrated a clear cost-benefit relationship.

Challenges and Overcoming Them

One common challenge encountered during true zero waste certification is the initial investment in infrastructure and employee training. Sustainable Solutions Inc. addressed this by securing funding through government grants and securing funding from investors interested in environmentally conscious companies. They also implemented a phased approach to implementation, starting with pilot programs and gradually expanding the scope of the initiative. This helped manage the transition effectively and minimize disruptions to operations.

Benefits of Achieving True Zero Waste Certification

Eco-Craft Manufacturing found that achieving true zero waste certification led to improved brand reputation and increased market share. This is because customers are increasingly conscious of environmental issues. The company secured new contracts and partnerships with businesses committed to sustainable practices, leading to increased profitability and market leadership.

Future Trends & Developments: True Zero Waste Certification Cost

Source: prc.org

The field of true zero-waste certification is rapidly evolving, driven by increasing global awareness of environmental issues and the need for sustainable practices. This evolution will continue to shape the standards, requirements, and ultimately, the cost and benefits associated with achieving true zero waste status.

Potential Future Trends, True zero waste certification cost

The pursuit of true zero waste is likely to shift from a singular focus on waste reduction to a more comprehensive approach encompassing the entire lifecycle of products and materials. This holistic view will emphasize circular economy principles, promoting reuse, repair, and recycling alongside innovative waste reduction strategies. Furthermore, there will be a growing emphasis on transparency and traceability throughout the supply chain to ensure accountability and minimize environmental impact.

Emerging Challenges

One key challenge lies in the complexity of achieving true zero waste across diverse industries and operational settings. Different sectors face unique obstacles in terms of material composition, infrastructure, and consumer behavior. The increasing cost of implementing zero-waste practices will also pose a challenge for smaller businesses, requiring creative financial strategies and innovative approaches to resource management. Addressing these disparities will require tailored solutions and a flexible approach to certification. Another key challenge will be maintaining the integrity and credibility of the certification process itself as it expands to new areas and industries.

Opportunities for Innovation

The evolving landscape of true zero-waste certification presents numerous opportunities for innovation. The development of advanced technologies, such as advanced sorting and processing techniques, offers potential for significantly reducing waste and improving resource efficiency. Additionally, the growing demand for certified zero-waste products and services creates a vibrant market for entrepreneurs and businesses committed to sustainability.

Evolution of Standards and Requirements

The standards and requirements for true zero-waste certification will likely become more nuanced and specific. Instead of a one-size-fits-all approach, future standards will likely incorporate sector-specific benchmarks and criteria, tailoring requirements to the unique characteristics of different industries. Furthermore, the criteria will incorporate evolving scientific understanding of waste management and the latest technological advancements in recycling and waste processing.

Impact of Technological Advancements

Technological advancements will play a pivotal role in shaping future zero-waste certification processes. The implementation of sensors, data analytics, and AI-powered systems will enhance waste monitoring and management. These technologies can help identify areas for improvement, optimize resource allocation, and provide real-time insights into waste streams. The development of innovative materials and manufacturing processes that reduce waste generation at the source will also contribute to achieving zero-waste goals.

Future Costs and Benefits

The cost of true zero-waste certification is expected to evolve in response to technological advancements and the complexity of implementing sustainable practices. While the initial investment may be significant, long-term benefits such as cost savings through reduced waste disposal, enhanced brand reputation, and increased consumer loyalty will likely outweigh the initial expenses. Furthermore, the increased efficiency and resource optimization brought about by true zero-waste certification could lead to substantial cost savings in the long run.

Concluding Remarks

In conclusion, obtaining true zero-waste certification involves careful consideration of costs, processes, and potential benefits. The financial implications, ranging from initial certification fees to ongoing compliance, need to be weighed against the potential savings, improved efficiency, and enhanced brand image. This guide has presented a comprehensive overview of the true zero-waste certification cost, equipping readers with the knowledge to make informed decisions about pursuing this crucial sustainability initiative.